Hydrogen Generator

Hydrogen Generator

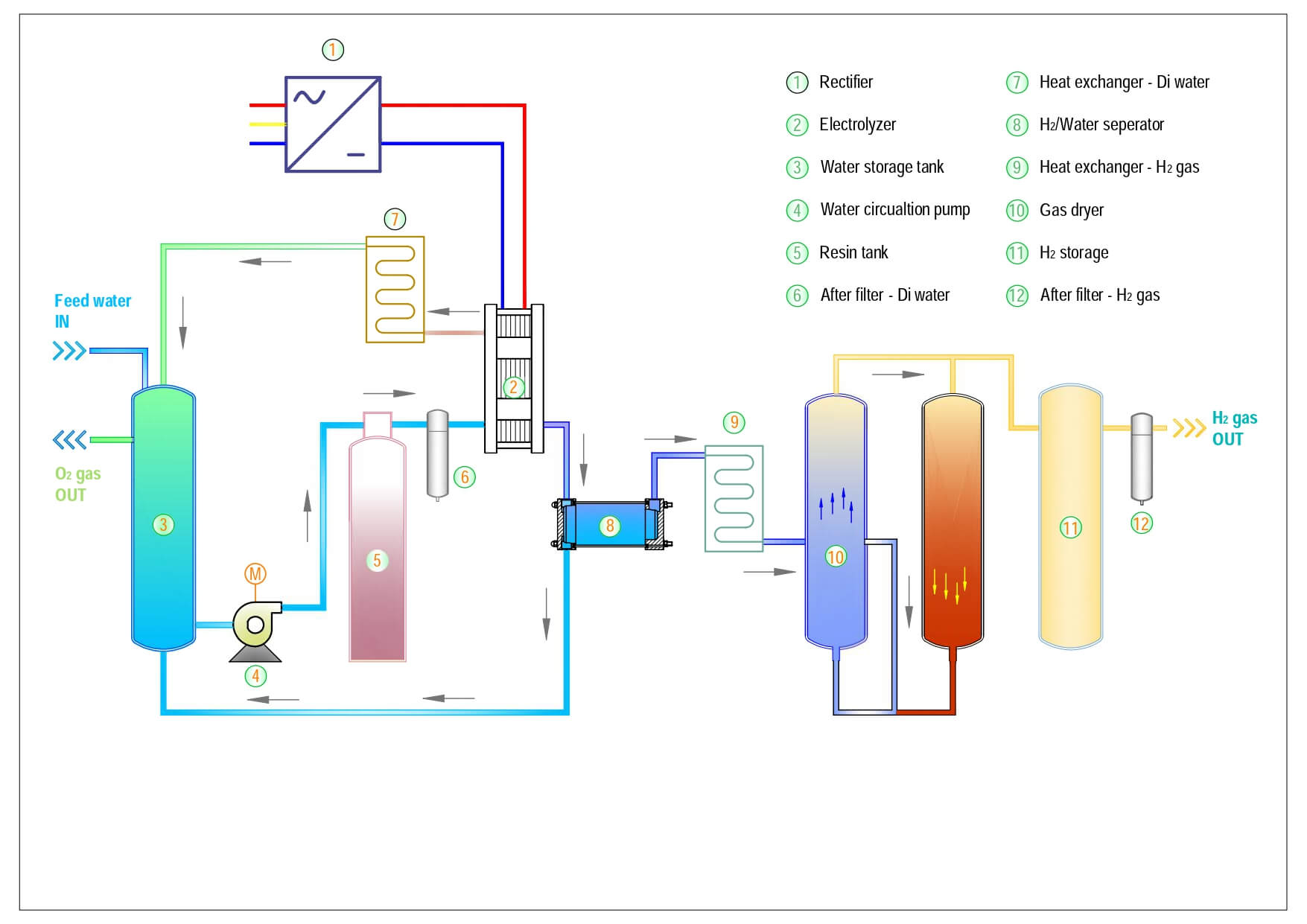

In both AEM and PEM electrolyzer, hydrogen is produced by passing electric current through water. The current splits the water molecules into H+ and OH-, then these ions combine to form Hydrogen, Oxygen and water molecules. Oxygen and water molecules are collected on one side of the membrane, while hydrogen molecules are collected on the other side.

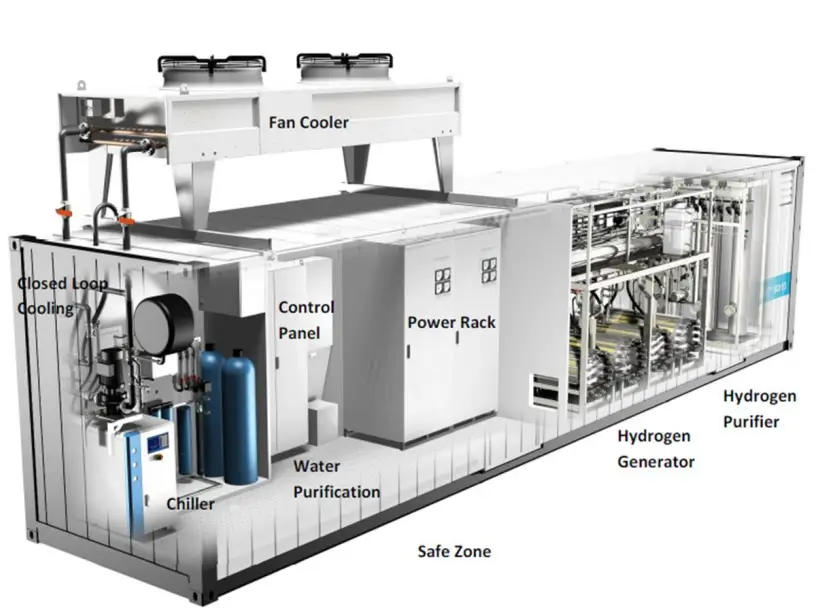

Summits electrolyser is highly efficient, reliable and durable, also modular and scalable, making it easy to deploy and expand as needed. The stack is more than just the core reaction chamber, it is the heart of the system, where the electrolysis process takes place. It is made of multiple electrochemical cells. Each cell contains an anode and a cathode separated by a membrane.

The power supply unit deliver the electrical current needed for the electrolysis process. It may regulate and control the voltage and current based on the desired hydrogen production rate.

The water feed system supplies purified water to the stack. Pre-treatment might be necessary to remove impurities that can damage the membranes or electrodes. After splitting water, the gas separation and drying units need to separate water / moisture from produced hydrogen and oxygen gas. This ensures that the obtained hydrogen meets purity and dryness (rH) specifications of various applications.

The control and monitoring system continuously monitors and controls various parameters like temperature, pressure, flow rates, and voltage within the electrolyser. It also includes safety features to shut down the system in case of abnormalities. The thermal management system which involves heat exchangers and cooling loops helps to maintain optimal operating conditions.